The Concordian

Issue #37, Spring 2004

Skip & Mistral Sail Away

As many of you know, Skip Bergman took over the reigns of the newsletter from Doug Cole in 1998. Since that time, Skip consistently devoted a tremendous amount of time, dedication, and enthusiasm to the newsletter and to the fleet as a whole. I can only thank him for the issues from 2000 forward, but in some way shape or form, I'm sure we all can raise a respective toast and say, "Skip, thanks for the memories!"

Well Here Goes

Welcome to the first try of a work in progress. Thanks to everyone who sent a kind note and/or a check. And a special thank you to the owners and others who took the time to put together an article for this issue. Those of you with a keen eye for detail may notice a few changes to the newsletter. A change that isn't obvious is that beginning with Issue #38, articles submitted will be posted online at www.concordiayawl.com. Currently it is a mirror of our website, www.sailingwithsarah.com, but if there is enough interest, concordiayawl.com can be a dedicated owners' site. Even for those folks who got shorted a mast, if you'd like to submit pictures, ship's logs, or other information, I can easily set up web page(s) for each vessel. Thus (yawl or not) you could have a website for your vessel, for example: www.concordiayawl.com/actaea. I use #17 as an example because Tony Harwell has always been wonderful (shall we say extra generous) in sending pictures and updates. Also beginning with the next issue, subscribers who have provided their e-mail address will receive a copy via e-mail in addition to the printed copy. By receiving a copy via e-mail, you will be able to access the newsletter from your computer, print additional copies for friends and coworkers interested in the fleet (and subscribing), and there will be active links to click on for more information and additional pictures.

Well folks, here goes ...

Java #1

Vagn & Sally Worm

Not much to report; JAVA is under the care of Bob Vaughan's Seal Cove Boatyard, Harborside, Maine. This is near Buck's Harbor at the Western end of Eggemoggin Reach. Her homeport is the Benjamin River, located about the mid point of the Reach between Brooklin and Sedgwick. Our small summer house is up the hill from the Benjamin River Marine boatyard and our shared dock is the one to the right of the boatyard dock. Concordias are always welcome and boatyard moorings marked BRM are usually available. As last reported, we did not get much sailing until the end of the last season, but it was really fun to sail into Padanarum as our first port after departing from IYRS in Newport, RI. Dan Strohmeier, MALAY, stopped by in the launch and was pleased to see the boat that started it all back in her old homeport even if only temporarily.

As we sailed only a few more days in 2003, 2004 will be more of a shakedown year for us. JAVA is virtually a new hull with most of her original interior intact. Her original spars were re-rigged back to the 1939 configuration. The hand-spliced rigging still needs to be fully stretched out. Beyond more painting and varnishing, Seal Cove Boatyard has installed a new Corcordia heater to replace the one she had originally. JAVA is scheduled for launch around mid May; after a long cold winter we can hardly wait to be in Maine and getting to know JAVA better.

Luna #88

Stephen Symchych

2004 marks our first full season of ownership of CY 41 #88 LUNA, ex-Renaissance. Margo's website recounts how she discovered the Concordia class after admiring this very boat in Newport several years ago. Our own route to her was a bit more convoluted, beginning over ten years ago when the notion of a Concordia found itself on our "someday" list. Like Margo, however, we found her to be everything we could hope for in a boat of her size. We were lucky enough to have come to her after her previous owners had done a great deal of restoration work. She came looking very clean with new-ish spars and sails to match, a new dynel/glass deck, new wiring, and a great deal of useful gear including a spiffy Harken traveler and roller reefing on the jib club. Our job has been to work on a few punch list items from the survey, and add some of our own gear to make it feel like home. The main task for the winter was to finish off the treatment of "41 Disease" -- replace the floors forward of the mast, and address the delamination of frames on each end of the hull. Concordia suggested using bronze floors, under the theory that they are less likely to induce electrolysis than the original galvanized iron. We'll be able to report on that after a few seasons; in the meantime, they look like fine jewelry. We will continue to monitor the iron floors in the main cabin.

We also had the topsides refinished -- it was time for this procedure -- and then replaced the diesel engine, which died in the fall and could not be rehabbed at a reasonable cost. (N.b.: never assume that valves will keep salt water out of your exhaust pipe.) Brodie MacGregor and Peter Durant have been great resources throughout, and the whole Concordia yard has done a fine job on these and many smaller projects.

As mentioned in the last newsletter, we commissioned a new pram from Jim Conlin's shop. He was superbly in sympathy with what we were trying to accomplish with this boat, and close enough to our home that we could check on progress through the winter. The dinghy looks lovely, has the capacity we had asked for, and has room for a sailing rig when the kids get older. We have named her Moth, and look forward to teaching the children how to row this summer.

Moth

Conlin Boatworks

Stephen Symchych, owner of LUNA, Concordia 41 #88 (formerly Renaissance), wanted a proper tender. His needs were for a dinghy which was aesthetically and historically correct, had enough capacity for his family of four and was reasonably rugged. And it had to fit on the coachroof. In selecting a design, we started with the Concordia Bateka, but considered a few other prams, too. It became apparent how carefully the original Bateka was tuned to its mission. Still, Stephen needed a bit more capacity, so we increased the beam by 6 inches while staying with the original 8'7" length and depth. The construction is 'glued lapstrake,' where the planks are of plywood, joined with epoxy rather than rivets. This is both more rugged and more tolerant of drying out than the original cedar on oak construction. It can be lighter, too.

Picking the Bateka design was made easier by the available documentation. Mystic Seaport Museum had several sheets of drawings including offsets and many details. Brodie MacGregor kindly found a drawing from A&R, which helped fill in more details. Most importantly, Mystic had an original Bateka, given by (Corinne) Mrs. Percy Chubb. Peter Vermilya, Mystic's curator of small craft was very generous in allowing me to view, touch, measure and photograph it. I can't thank him enough. With all this help, mimicking the details of the authentic Bateka was easier.

We could not find plywood of a wood species whose grain and color harmonized with the Concordia's mahogany surfaces and of the needed structural quality. We were lucky to find some very high quality 1/16" Honduras mahogany veneer which was a faithful match, so we made our own plywood, vacuum bagging this with epoxy onto 1/8" BS1088 okuoume ply. It finished nicely and the extra-thick face veneers look better at the edges and will be more damage tolerant than the thin-face veneers of commercial plywood. The finished dinghy fits cleanly on LUNA's deck, clearing the ventilator. The finished weight, with cushioned gunwale guard, is 100 lbs. The carrying capacity, by USCG measure, is 4 persons or 583 lbs. Of course, for Concordia 39 owners and those not needing the capacity, it could just as easily be built to the original breadth. It would be about ten pounds lighter. In either case, they represent an alternative to the 'plastic radome' look of fiberglass prams.

More photos are posted at http://www.conlin-boats.com/baeteka.html

Jim Conlin Conlin Boatworks Wellesley, MA 781 237 7564Concordia Company, Inc.

South Dartmouth, MA

SNOWBIRD #59 is in outstanding condition and surprised us all by developing a very significant leak a couple of weeks after launching this Spring. Water was coming in from either side of the stern post, and when we hauled there were no obvious problems on the outside. By process of elimination we decided that the shaft log (lead pipe through the stern post surrounding the prop shaft) must have failed, and this turned out to be the case.

Repair involved removal of the shaft, removal of the badly corroded lead shaft log, fabrication of replacement shaft log (in this case out of brass) and reassembly. Corrosion of the lead shaft log was most pronounced where the two (copper ) tubes direct water from the scoops on the outside into the shaft log to ensure plenty of water at the cutlass bearing. In the SNOWBIRD case rather than trying to create a waterproof connection between these two copper tubes and the brass shaft log, we upgraded the original stuffing box with a water injected PSS shaft seal set-up. This provides plenty of water to the cutlass bearing.The hardest part of the repair is properly flaring one end of the brass shaft log, installing the new log from forward by lifting the back end of the engine, and properly flaring the aft end of the log in place so it seals and fits properly under the cutlass bearing SNOWBIRD is back on her mooring and ready for a summer of sailing.

Boats for sale. Recently listed TAMBOURINE #97 is under agreement and should be in new hands in a couple of weeks. The only remaining boat we have listed for sale is BEAUTY #53, which is a very nice 41. Asking price is $150,000, and she will be in the water mid June.

We hope to get a start on the restoration of DIABLO #95 this summer. Our most recent restoration on SAVU #92 is almost complete and she will be launched the second week of June. CORIOLIS #82, which we rebuilt last Winter to repair damage incurred in the Seattle Yacht Club fire, is scheduled for mid June and will spend the summer cruising in New England before returning to Seattle in the Fall.

Brodie MacGregor

ramacgregor@concordiaboats.com

Lotus #15

Chris & Kathy Grace

Lotus has been in our care for almost two years. She came to us as Sovereign (#15) after a long stay on the hard. She had been carefully tended to, but had seen little time on the water, a condition we have earnestly set about to remedy. We were fortunate that much difficult and time consuming work had been accomplished before she came into our hands. Not that there wasn't plenty to keep us busy and supporting the local maritime trades. Port Townsend has an incredible resource of talented and knowledgeable craftsmen, and with no previous experience maintaining a wooden boat we took full advantage of their patience.

After a few all too short sails she was back on land stripped of paint and varnish with her masts lying along side. After a thorough inspection and minor repairs we began to gain the kind of intimacy only a few months with sandpaper, paint and varnish seem to bring. Brion Toss completed the new standing and running rig, including a new mainsheet system with traveler. We revised electrical distribution, added radar and GPS and ordered a new suite of head sails. Earlier this year, Sean Rankins of NW Sails took us tirelessly through the process of building a new mizzen and a fully battened main. He also completed an asymmetrical with a brilliant graphic my skill is not worthy of. As stunning as she looks, it is the expression on the face of someone taking the helm for the first time and pointing her to windward in 15 knots that tells the story. Growing up in New England I had always admired (lusted after) Concordias in the way adolescent males arrive at an awareness of universal truth and start staring tirelessly at pictures of E-Type Jaguars, P-51 Mustangs and Norton Manxs. ...but I had no idea of the truth, until we took her for the first time beyond Point Wilson in a stiff breeze.

Perhaps the best part of the experience has been sharing it with Kathy, who had virtually no previous sailing experience, but has given no quarter. Sailing dingys, catamarans, Etchalls, and J Boats, she has become amazingly accomplished and bares the greatest burden of the work, from splicing double braid and stooping for hours in the sail loft to climbing the mast. We are especially grateful to Alan Preston, who never recovered from his experience working at Concordia, and Scott Flickenger who is endlessly amused by our efforts and keeps us from straying too far.

Chris Grace

PS Does anyone have polar tables for the Concordia?

Wild Swan #25

Peter Costa, Mattapoisett, MA

Wild Swan was launched early spring and is floating high, dry and happy awaiting sea trials after a major structural rebuild.

Today she is virtually a new boat and while some projects still remain on the "to do" list, she is structurally more sound than the day she was first launched 49 years ago.

To return such a boat to its youth is an enormous emotional commitment for an owner, one which truly grows into a labor of love. Wild Swan was fortunate to partner with her new owner, Dave Smith, for he made the commitment early on in the project to do everything right the first time around. Projects such as this are also exciting for a boatyard to undertake and a part of everyone at Triad sails off with Wild Swan as she enters her second life.

Listed below is a partial summary of the new work required on Wild Swan:

|

|

Additional information can be found on the owner's website at: http://homepage.mac.com/wildswan

Other Concordia Projects

This season we are wooding and refinishing the topsides on Loon, #45; have installed a new head and reworked the holding tank; and are doing minor repairs, in addition to paint and varnish. Feather, #29 (41) is having the bottom stripped, minor repairs made, head seacocks replaced, and routine paint and varnish. Envolee, #81 is having her normal, routine winter paint and varnish work and Captiva, #100 is having her topsides wooded and refinished. In addition to routine brightwork maintenance, she has also had three keel bolts replaced and has a new 3-blade propeller.

Irene #103

Doug Cole, Bellingham, WA

First, my sincere thanks to retiring editor Skip Bergmann for his fine work in publishing the Concordia Newsletter from 1998 to present. Skip was one of the earliest subscribers and his address in central Wisconsin often had me wondering what possible interest he could have in the Concordia class. In 1994 he purchased Paramour from owners who kept the boat on the coast, over five hours from where they lived in Atlanta. Skip did a beautiful upgrade on Paramour when he kept her near Sturgeon Bay and then moved, with the boat, to Falmouth, MA. When I started the CNL in 1985 I had not even thought about succession, but again, my compliments to Skip for a job well done! Now let's give Margo Geer the support needed to keep the fleet together and well informed.

My only major winter project this year was installing new propane burners in the galley stove. Irene came with the original Wilcox Crittendon alcohol two-burner stove. I have never been very enthused about alcohol fuel and in short order converted the burners -- actually removed them, the tank and pump mechanism -- and replaced them with burners from a cast iron camp stove, the only thing I could find at the time. They cooked quite well, however, they produced an unacceptable amount of soot on the base of the cookware. I changed jets, adjusted dampers and modified regulators, all to no avail.

Over the years I kept my eye out for different stoves or burners. New propane stoves simply did not fit the space and modification of the existing space would entail a complete remodel of the galley. I tried to find individual burners, even to the point of buying several RV stoves in an attempt to separate out the burners, but nothing seemed to work. Finally, I came across Paul Luke's website and found that he had a nice stove available, but still, it did not fit the space. I called to inquire about the possibility of adapting his burners to my WC stove and learned that the source for his burners was Force 10, which was only a short distance from me in Richmond, BC.I called Force 10 and they shipped the needed parts for the project. These consisted of two 8000 BTU burners, valves, gas lines, compression fittings, adapters, thermocouples and seals. I made up a manifold out of copper pipe, a friend cut out burner and valve brackets out of stainless using a plasma cutter, then I assembled it in my shop, which I call "CSF," or Concordia Support Facility.

Last week I cooked my first meal on the stove and I must say it's a nice improvement. The galley still looks original but the stove is now modern in its operation. If anyone is interested in the project I do have templates for the brackets and a parts list from Force 10. douglascole7@cs.com

Abaco #102

Jonathan & Dorothy Goldweitz

It is the 5th of May and Abaco is finally off the dock. I roll out the jib, kill the engine and am finally sailing, heading west on Long Island Sound. I never thought this day would come back in January. The weather was frigid, and we were spending the weekends splitting firewood and skating on our pond instead of stripping varnish from toerails and cabin top moldings.

Gradually, we started getting to Hamburg Cove more often, finished wooding the worst of the brightwork and completed some of the small below deck projects begun in the fall. Abaco was ready to launch by mid-April, but other boats blocked the short path to the travellift from her spot in the Cove Landing Marine main shed. She was finally launched, and as we packed the car on a Friday to spend the weekend getting Abaco commissioned, Dorothy's mother was hospitalized. Our focus and plans quickly changed, and her mom died a week later. Springtime boat preparation at "The Cove" became a distant memory as we spent all our time with Dorothy's father and siblings. But while we were away, John Leonard and his crew knew how important this old yawl is to us, so he stepped the rig and commissioned the engine; Dorothy, her father and I spent the next weekend doing intensive commissioning work aboard, and Abaco was ready to sail. Going for an afternoon sail or taking a long cruise has always been "good therapy", but I was impressed how good it was for Dorothy and her dad to immerse themselves in stowing gear, bending on sails, tensioning lifelines and sorting out running rigging.

Abaco was not ready to leave for Stamford quite yet, however. Yard owner John Leonard was planning to launch Duster, his restored 48-foot S&S sloop built in the early 1960s. After having Abaco rafted to Duster before hauling in the fall of 2002, and watching the two winters of her restoration in an adjacent shed, we just had to be there. As a crowd of local boaters and friends gathered, we dressed ship and saluted with our canon as John lowered Duster from the travellift. She still had a lot of deck and rigging work to be done before she sails, but she will look magnificent when she joins the S&S and IYRS cruise fleets in July.

The next morning we awoke to brilliant sunshine with a 37 degree chill, a thin layer of ice on our decks and Abaco's keel in the mud at the Cove Landing float. After a hot bowl of oatmeal and a second cup of coffee, we were again floating and I was able to back off the dock with John Leonard and Dorothy carefully tending the lines as we slipped past Golden Goose, a well-known Hamburg Cove schooner. The trip out of the Inner Cove, down the Connecticut River and out on to Long Island sound was almost magical as I relished being underway once again. Many friends ask to help with this annual spring "delivery cruise", but in going by myself, I really get to enjoy how much sailing Abaco has meant to me as we begin her 36th season together.

Summer cruising plans are not definite yet, but, hopefully, will include joining the IYRS Classic Cruise fleet in July and then visiting with family in Nantucket. We hope to see many of our Concordia friends out on the water this season.

Misc. News & Notes

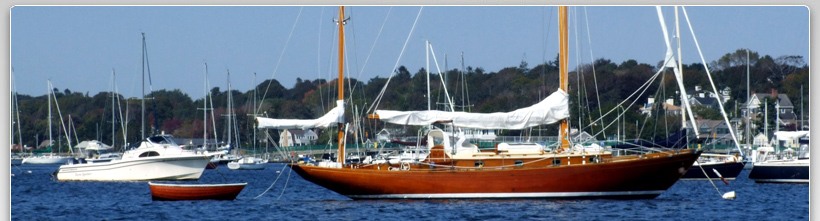

A reminder to all not to miss the 2004 CYC. The picture on page 8 is just a small taste of scenes from the 2003 CYC -- contact Marcia Whitney @ (401) 849-3060 for more info on the 2004 cruise...Phyllis Winstral and Jonathan Miller have a mooring in Bucks Harbor for Mistral (#72) and invite any Concordia owners in the area to give them a call and use the mooring if it is empty. (212-477-3747)...John Heubi of Tempo (#4) continues his restoration and has a Woodmizer portable sawmill and plenty of white oak in his part of Tennessee...WoodenBoat issue #178 featured Coriolis' restoration..William Fitzgerald reports building a shed to house Tosca (#73) for a refit prior to building his house (priorities in order obviously)...Captiva (#100) spent another winter under the loving and capable care of the gang at Triad. This year's major project was removing 39 years worth of topside paint and starting over. She also got another 3 keel bolts. This summer Captiva will be a part of the IRYS Classic Boat cruise and John and Laurie urge other Concordia owners to do the same. Otherwise they will be sailing the waters of Buzzards Bay and the islands... Tony Harwell of Actaea (#17) (772) 286-5330 - captboo@bellsouth.net has quality US-made bronze screws. Contact him for prices.

Off Call #58

Peter Castner

Not much of a work list this winter to report on for Off Call. I guess going totally nuts ($) the last two winters finally paid a dividend and we got a year off! The varnish work is completed (looks wonderful), and the hull just got painted. Interlux Paint, being part of a huge marine conglomerate, decided in their infinite wisdom to stop producing the Off Call "signature" (gray) hull paint. Wayfarer researched it and came up with a close match with another paint company, and I think it looks even better! I can't believe either the depth or shine. To think I almost skipped painting the topsides this year.

We are back in the water as of May 12th. Absolutely the earliest launch in my ownership. Reports are that the bilge is dry -- ALWAYS very good news. Sticks go in next week.

I'm really in favor of being first out in the fall, before the Hurricane season, and first in the water in the spring. This seems to work out pretty well. It gives the hull some time to slightly dry out before it's too cold and then get back in before she dries out. We are now storing and sailing out of Wayfarer's in Camden, Maine. The care and detail these folks bestowed upon Off Call has been nothing short of stellar.

We started out further south, but heck we were never on our mooring there. I figured, cut to the chase and keep my beloved Off Call right where we always end up anyway. I've found no better place to sail out of then Camden. I'm looking forward to a season of cruising and ... just hanging out on board.

I finally broke down and bought my two sons a new outboard. We went from a twenty-year old ancient and sometimes reliable 9 HP Johnson to a new 15 HP Yamaha. On our rigid bottom inflatable, it is one fast beast. But you have to keep the crew happy. That baby sees a lot of miles in the summer as my sons and their friends venture out.

Well it has been 14 years and we are still going strong! Peter &Crew

Mystery Photo

J.P. Sumner sent this picture he took in August of 1954 after Hurricane Carol. His notes say "Sister to Malay " and the picture was taken at Thomas Boatyard (now known as Dodson Boatyard, Stonington, Connecticut)

Golondrina #65

John Eide

I really have no great news this time. After having spent 15 months last year sailing Golondrina between Maine and the Caribbean, life is a little slower now. The big news is that Golondrina will not be going in the water this summer since she needs a new horn timber. When I launched her in June of 2002, I soon discovered an unstoppable leak just aft of the rudder post tube. Two months later I rehauled, beat, bedded and fastened a sheet of copper around the fairing piece aft of the rudder post on the outside, dug out a large handful of rot on the inside and filled it with Git-Rot and chunks of oak all capped over with a well-bedded piece of locust. This patch job held up through the trip south and back, but now it is time to fix the problem properly.

I plan to dig a hole, drop the rudder, move the engine and fuel tank out of the way, cut out the transom, pull a ton of fasteners, get the rudder post tube out, unbolt the floor timbers and remove the old horn timber. Then I'll fashion a new one out of laminated mahogany, put it in, refasten the floor timbers, bore for the rudder tube, stick it in, refasten the planks, clean up the fuel tank, repaint the engine, redo the fuel filter system, install the rudder and paint. I'll also connect the backstay tang to the horn timber, which I'm surprised was never done originally. As Kerstin wrote in the last newsletter, that seems to be another design flaw and a weak link. All this should take slightly longer than it took to write that paragraph. Golondrina is now 48 years old and has never needed any serious structural work, so I really can't be too upset over this turn of events.

When I think that she sailed from Los Angeles through the Panama Canal and up to Connecticut in the late '50's, then to Maine, the Chesapeake, before heading to the Caribbean where she sailed the islands for 15 to 20 years, I realize she's had an active sailing life. I bought her in 1991 and sailed her to Maine, where I restored her cosmetically before sailing her back to the Caribbean. Twice. She's in really great shape for a middle-aged yacht. I will not be going offshore in Golondrina again since I feel she deserves a nice quiet retirement cruising the Maine and New England coast.

Which brings me to my next topic - I have a few offshore items that I would like to sell: 6 person Lifegard offshore raft in valise, packed and inspected in 2002 with VHF locator - $375; 2 folding bikes, both old 3 speeds, one a 16" Dahan, the other a 20" Yugoslavian - $100 takes both; 100' 1/4" high test galvanized anchor chain - $50. And, some good stuff: Original! c1958 Concordia Heater. Rebuilt, recaulked, and reblackened. Never installed or used. It was purchased as a spare when the boat was originally ordered $3,000; set of three A and R bridge deck blocks. New bearings, wrought iron eyes restored, swivels work, one of the three bails needs rewelding, ash shells show wear and need varnish $200.

I'm willing to deliver any of the above anywhere in Maine or as far as New York City.

You can reach me at jeide@meca.edu or 207.883.0973

Mystery Yawl

The Eggemoggin Reach Regatta didn't have much wind or sun, but I did have some pictures turn out pretty well considering...Will the owner of the yawl with the yellow logo and sail numbers please step forward? I have several good pictures I'd love to e-mail you.

Actually, I have quite a few pictures and we're working on a slide show from the ERR. Please check our website at www.sailingwithsarah.com/ERR2004 - Margo

Hero #22

Rick & Donna Peck

Well, Hero has been in the water all winter and she has faired very well, despite the extremely frigid temperatures. Cove Landing again did an excellent job looking after her.

We will soon be giving her topsides and bottom a fresh coat of paint. Up to now, we have been taking care of projects like re-wiring cabin lights, painting below and washing down all the interior woodwork. On deck we have sand painted her deck and cabin top with two coats including cutting in some waterways, to give her a fresh look. Varnishing is almost complete with a little work left to do on the toe rails. We are hopeful to get her back to her mooring in the Thimble Islands by the end of May to enjoy the season.

Our cruising plans this summer will take us up to Fisher's Island, Block Island, Newport and up to the head of Narragansett Bay and back in late July. We are also planning several weekend trips up and down the Sound and hopefully we will see many of you this summer.

Thank you to Jon and Dorothy Goldweitz of Abaco for some helpful ideas on hatch board stowage, code flag set up and take down strategies and pigstick delivery. Also, it was great they could share with us their awning dimensions.

Fair Winds to All

Cockpit Seatbacks

Skip Begmann

When I owned Mistral, #72, the cockpit seatback hinges were screwed into the teak deck. This worked fine, except over the years the holes enlarged, larger screws were required, and rebunging the holes with end grain plugs obviously was not a very effective solution. Through-bolting the hinges is the way to go, but on this boat you could not get to the underside of the aft deck due to a lot of structure being in the way. I solved the problem by making brass plates with tapped holes and permanently screwed them to the deck. I then used short bronze machine screws to bolt the hinges to the plates. The seatbacks could be removed by just screwing out the four machine screws. This worked pretty well using the brass I had on hand, but using bronze or stainless plates is the best way to go, since they would hold threads better.

Dame of Sark #86

Steve & Nancy Donovan

Two notable items:

2004 Newport Bermuda Race

The 2002 event was an unpleasant but ultimately very satisfying and uplifting experience...so we're going to try it again. Improvements to the Dame aimed at improving crew comfort include a new sea hood, gimbaled CNG stove/oven, and DC refrigeration. Report in the fall issue.

Martha's Vineyard -- Round the Island (RTI) race

We have competed in this event for the past three years, and each time we have won the Cruising class. The Dame isn't that special and we're not that good. This race likes Concordias. The event is scheduled to avoid strong opposing currents. This allows the course, fifty-two miles in length, to be completed by early evening -- typically before 6:00 PM. It is great fun. We'd like to see more Concordias. This year's race will be held on Saturday, July 10. If you come be sure to look us up to share some hospitality. In Edgartown...508-627-3577, or spd4141@aol.com. For more race info go to rtirace.org. The Edgartown Yacht Club should have the '04 race materials available by the time you receive this newsletter.

Actaea #17

Tony Harwell

FALL 2003 As I mentioned in issue #35, I was in the process of locating some Black Locust. After a long exhausting search I finally located some at New England Naval Timbers. I finally got half of a tree delivered to my doorstep and promptly started carving it into a toe rail. Out of all of the stock, there was barely enough for the toe rail.* I believe that this toe rail is the hardest thing I have ever built. I plan to work on the hull next. It needs to be sanded, primed, and painted. After that I'm going to re-caulk the bottom, throw some bottom paint on her and dump her back in the water. It sounds easy but a lot more work goes into it. *We also had a similar expensive lesson learned courtesy of New England Naval Timbers. -- Ed. I went to the Wooden Boat Show in Rockland, Maine, and saw a lot of nice wood boats and was able to find a compass plane, which I have used quite a bit on the toe rails. While I was up north I went by Mystic Seaport and did some research on Actaea, stopped by IYRS and saw Java floating, (SWEET!) and saw several other Concordias. The highlight of the trip was going sailing with David Catlett on #7 Aureole. We left his mooring in the afternoon in a brisk breeze on our way to Newport Harbor. This was the first time I had sailed on a Concordia and she sailed like a dream. As we sailed into the harbor the breeze let off, and David sailed us through a maze of the finest yachts I have ever seen. It was amazing how David and the boat sailed in the light wind as we weaved through the anchorage. As the sun lowered we landed at a dockside restaurant. After we got a bite to eat we stumbled down below for some shuteye. I got the pull down berth in the main saloon and David slept forward. I don't know if my bed at home is really bad or I drank too much, but that was one comfortable berth! The next morning we left the harbor and had a nice sail back. (Thanks for the adventure David!)

Spring 2004 Well, I finally finished the toe rail and promptly started on the cockpit and combings. The cockpit sole needed some attention in the form of 2 new beams and refastening. I replaced all the bolts and fasteners in the cockpit sole and then re-caulked the seams. As soon as I finished the sole I started on the sides and combings. I started the combings prior to the sides because it seemed easier to fit the sides to the combings than visa versa. I built a 14' steam box in my backyard and rigged a cooker to make the steam. I also made a form to bend the combings over. I soaked the wood in the water for about a week and a half then shoved them in the steam box for about an hour and a half. When they finished cooking I bent them over the form and let them set. Unfortunately the form was not a strong enough bend. So I had to rebuild the form and steam the combings again. Has anyone ever tried to stuff a bent piece of wood back into a SMALL steam box?? It's not easy, but I accomplished it and finally got the right bend. I fit them to the boat and then built the cockpit sides.

After finishing the cockpit I figured it was time to start on the topsides. I had to refasten a lot of the planking at the widest points of the hull. Not that the screws where bad, but they were not tight enough. This also was the area that had been refastened. It was about 15' feet of the middle section of the boat. I sanded, refastened, primed and painted the port topsides and it came out O.K. I then started on the starboard side. This side I attacked a little differently after finding a bad plank that ran to the transom. While replacing the plank I found that the screws had never been replaced as told to me by the previous owner. So! I started refastening her entire starboard side. The fasteners came out very easy and were still strong and tight, but I could tell this was the time to change them. So now the entire starboard side is refastened and unpainted and the port side is painted but not refastened. Do you think she'll sail crooked? Don't worry! I'll refasten the port side also. It's going to be a lot harder to find the wood plugs now that it's already painted.

She has a lot of paint on her topsides and has never been wooded. The cove stripe was a lot smaller with the build up of paint, but I was able to chip it out very easily down to her original size. Had a short visit from Dave & Margo Geer. It's always a pleasure visiting with Concordia owners, but really nice visiting with Dave and Margo because they are doing a lot of the same things I am doing and more. Also, I had a very short visit from David Catlett. Simple truth is we're all crazy, and it's just great to be around your own kind.

Powerplant: Perkins 4-108. Actaea had sunk at the dock a couple of times prior to my ownership. When I bought her a friend and I removed the engine and dismantled it. It has been 3 years now and the engine is back in one piece thanks to my friend and his son. When putting it back together they found that the piston rods were too big for some reason and they were banging the bearings pretty bad. It was good that it only had about 10 hours on it. Rods are pretty expensive so I bought a used engine for parts. It has all new parts including starter, and alternator. It's not in the boat yet, but will be soon.

I lost my canopy in a windstorm a few weeks ago and it's beyond rebuild so I guess I'm going to leave it down. I still have a lot of work to do and I told myself I would be splashing sometime this summer. I hope it's a long summer.

I am looking for a Wood mast for a 41-footer. If anyone wants to get rid of his or hers, or trade for an aluminum one, please let me know.

Good yard sailing to all! (Actaea #17) Tony Harwell (772) 286-5330 - captboo@bellsouth.net 546 S.W. Riverview Avenue Stuart, Fl. 34994

Sarah #27

Dave & Margo Geer

(Somehow in the excitement, challenge, and confusion of taking over the newsletter, I neglected to write anything about Sarah.)

For the third year in a row we found ourselves closing down the "Sarah Project" in early November because of multiple family and holiday commitments. However, this year the shutdown continued several additional months because we bought a house in December (actually Dave bought a four-car garage/workshop and I'm just darn lucky there was a house attached). At any rate, our self-imposed March 1st deadline to get back to work on the boat came and went and it was the second week in April before we were able to finally have a Sarah Day.

I spent the first couple of hours using my face as a cobweb removal device while Dave cleaned and organized. Since then he has replaced four of the floors and repaired several frames under the engine bed. He has another floor out to make a pattern for the replacement, and the next order of business is the stern knee.

Dave found the bronze frame straps just aft of the stuffing box deteriorated, but the frames were in good condition. He ordered bronze flat bar from Atlas Metals to make new straps.

As I crawled aft to get a picture of some of Dave's work, my joy was effectively doused when I looked up and saw the underneath of the cockpit floor.

From the picture in Waldo's book, we were aware that Sarah had pedestal steering at some point and had never really paid much attention to the large plate in the center of the cockpit. From the looks of it, when the pedestal steering was removed, this cockpit table holder was fashioned and unfortunately it caused a good bit of damage.

Finding a silver lining in every cloud, Dave has plans to rebuild the damaged beams and cockpit floor and incorporate not just a Giffy Full inspection plate, but to make a portion of the cockpit floor removable for engine and stuffing box access. As with most of the of the forward floors, Dave reinforced several of the new floors by laminating a piece of white oak cross-grain to the floor. Fifty or sixty years from now when she is undergoing her next rebuild, we figure someone will either thank him if it stopped the tendency for major splitting or wonder why in the world he went to all the extra trouble. Basically Dave has taken each piece and not only built a replacement, but crafted an improvement designed to head off the previous cause of destruction. In places where the floors had a definitive split, he's laminated a cross grain piece. In places where the floor bolts pulled through or damaged the frames or floors, he's made large wood washers or bronze backing plates. It is hard to see in these pictures, but the worst areas of damage to the floors correspond to the frame bolts.

Rereading the last newsletter, I note that we were about to try sandblasting the overhead with walnut shells. I truly believe that it would be feasible to spend a day and blast with walnut shells instead of the dozens and dozens of hours needed to scrape and sand the overhead, but it was an exercise in misery for us. Dave was suited up in full protective gear and my position was on the foredeck out of harm's way and ready to refill the hopper via funnel and hose through the forward hatch as needed.

Dave built temporary floorboards and even installed a brace to hold the hopper, but to sandblast the overhead in the forward cabin you need someone with the size, dexterity, and endurance of a 10-year old. Even folded up like a pretzel working in a brown blizzard, Dave did a wonderful job on the underside of the deck, but when the dust settled, there are areas of the oak shelf where the walnut shells damaged the grain and the wood is going to have to be filled before it can be painted. After just a few hours we abandoned the project and in my spare time (Laugh) I'll just have to use the tried and true heat gun and scraper. Days later when I took the air hose up forward to try to blow out the pounds of walnut shells accumulated in every recess and orifice, it was like being caught in a demented brown snow globe. I've since blown her out on several occasions and done two complete washes -- those of you who don't have your garboards off don't know what you're missing to be able to take a hose and a bucket of water inside and do a car-wish style scrubbing on the interior.

Again, for a working yard (or person) that sandblasts routinely and has professional equipment, I think sand/walnut shell blasting would be a very viable option to remove the paint on the overhead. With an interior removed for major work, you could tape off any areas of concern and blast the paint right off the overhead -- adjusting the psi according for the underside of the teak deck and the oak beams and shelf.

Even though it's the bilge, I'm still having a problem covering Dave's cabinet grade work with red lead, but, inspired by Praxilla's wine cellar (aka bilge), Dave found a Benjamin Moore paint that amazingly covers the red lead. So I have some solace knowing that we'll be covering the red lead in strategic places with a nice beige paint. Said beige paint serving the dual purpose of soothing my sensibilities and readily showing any leaks, stains, or problems.

Like Actaea, Sarah had sunk at the dock twice prior to our purchase. Even though the water did not get in the engine, it did get over the gearbox. One of the first things we did in 2000 was remove the engine and place it in storage. With plenty of room in his new workshop, Dave took the Westerbeke 4-107 apart for inspection. While the engine could be rebuilt, the old manual gearbox is a ball of rust, so we will repower when the time comes. The current plan is to go with a Yanmar 3JH3E 40 hp.

Boats for Sale

| # | Name | Price | Seller |

|---|---|---|---|

| #53 | Beauty | $150,000 | Brodie MacGregor |

| #76 | Sumatra | $120,000 | Peter Crane Yachts |

| #35 | Memory | $35,000 | Cannell, Payne & Page |

| #52 | Banda | $128,000 | Dodson Boat Yard |

| #11 | Take Five | Peter Gallant | |

| #80 | Golden Eye | $97,500 | Dion's Yacht yard |

Schedule of Events for 2004

NYYC Invitational Series

150th Annual Regatta

June 11th - 13th

Enter Online and get SI's from www.nyyc.org

NYYC Race Week

July 17th - 18th

Museum of Yachting's 25th Annual Classic Yacht Regatta

Sept. 4-5

Black Duck Regatta

Newport July 3rd and 4th

IYRS Cruise

July 11th-15th

www.IYRS.org

This event speaks for itself. It is the "Must do" event of the season.

Register early -- spaces available on Arabella as well !!!

WoodenBoat Regatta Series

EGGEMOGGIN

August 7th

Opera House

August 15th

Musuem of Yachting's 25th Anniversary Classic Yacht Regatta

Sept. 4-5

Governor's Cup

Essex, CT

Sept. 11th

Mayor's Cup

NYC, NY

Sept. 18th

Greenport Classic Yacht Regatta

Sept. 25th

Race Rock Classic Weekend

October 2-3

Newport Wooden Boat Show

July 23rd - 26th

Feeder Race to Maine

July 30-31st

Castine

August 3-5th

Eggemoggin Reach

August 8th

Closing Notes and Blanket Apology

As I finally close in on the printing of the newsletter, I find myself bruised and battered from sliding up and down the multiple learning curves associated with compiling the volumes of information received, learning new software (Microsoft Publisher 2003), and matching wits with a new color laser printer. If any of readers have experience with Publisher 2003, please give me a shout. Other than the fact that God hates me, I can find no logical reason why not once BUT TWICE after carefully saving hours of work I reopened the newsletter to find several pages of settings and images altered or missing.

I still have the challenge of "catalog mail merge" ahead of me -- said process purported to print each recipient's information on the last page of the newsletter. If your information is printed on the newsletter it miraculously worked. If there is a regular mailing label on your copy, it's safe to say that I'm still cursing the six-headed vermin at Microsoft.

In processing the volume of information into the newsletter and creating the database, it is quite likely that errors were made. Please accept this blanket apology if your name, your boat's name, or your dog's name is misspelled. Just let me know, and I'll fix before the next issue. If there is some atrocious gaff like the wrong boat pictured in your article or if I show the Goldweitzes owning DIABLO and Brodie selling ABACO, please forgive me! Then kindly shoot me!

Most importantly, if you sent me something or pointed out a previous error and I missed it, I am sincerely sorry. I'm fairly organized by nature, but this experience is proof positive that you can never be too organized. It has also been a wonderful challenge and learning experience, and I thank you all. I could easily spend another week tweaking fonts, colors, and layout, but with my right ear still ringing from Dave's "GET IT IN THE MAIL!!!" I've controlled my obsessive-compulsive side to the greatest degree possible, hit print, and tried not to look at or re-edit any of the pages.The deadline for the Fall issue will be October 15th, and you can expect the newsletter in your mailboxes the first week in November. Feedback is welcomed and appreciated, and if you haven't sent any information in recently, now might be a really good time to make sure the fleet knows your latest news. Subscriptions will stay $10.00 for the remainder of this year. After that I will look at the actual costs of the color printing and postage -- offset by paid subscriptions and contributions -- and determine what it will take to keep the newsletter a viable tool for Concordia owners and admirers.

Checks should be made payable to Margo Geer not The Concordian, and mailed to:

249 Argonaut Road St. Augustine, FL 32086

Cheers!